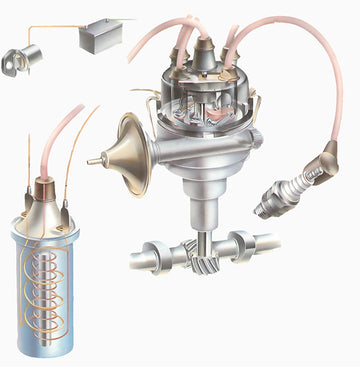

Ignition system is an important part of the gasoline engine. The ignition system has much effect on the engine power, fuel consumption and exhaust pollution, etc. The engine ignition system is all the equipment that work for edm spark between the two electrodes, which is composed of battery, generator, distributor, ignition coils and spark plugs, etc

Major classifications

The ignition system can be classified into 4 types, which are contact type (traditional ignition system), non-contact type, non-mechanical advancing type and distributor type. The development of non-contact ignition system means the elimination of traditional ignition system. it was soon replaced by the electronic ignition system. According to the different operation mode, engine can be divided into the Spark Ignition (SI Spark Ignition) engine and Compression Ignition (CI Compression Ignition) engine. gasoline engine belongs to Spark Ignition engines, diesel engine belongs to the Compression Ignition engine. Gasoline engine belongs to spark ignition engine, so the ignition must be done with the ignition system.

Primary function

Ignition system can work in any engine speed and under different engine load, which can provide enough voltage, and sufficient spark for the best engine combustion efficiency.

Operating principle

Gasoline engine ignition system is the device for an electric spark ignites. It can provide enough energy of high voltage to the spark plug in a cylinder ignition sequence, and make the spark plug electrodes produced sparks, so as to ignite the compressed combustible mixture in the cylinder.

Operating requirements

When the spark plug electrode spark breakdown and required voltage is called the breakdown voltage. The secondary voltage of ignition system must be higher than the breakdown voltage.

2, spark should have enough energy

In order to guarantee the reliable ignition, high-energy electronic ignition system should have 80 ~ 100 mj spark energy, and more than 100 mj spark of energy when starting.

3, adapt to the working condition of engine ignition

First of all, the ignition system should be ignited according to the engine working order. Second, ignition must be done at the best time.

Common fault

1, the fault classification:

Ignition system fault can be divided into two kinds of circumstances according to its position in the ignition system, that is the low voltage circuit failure and high pressure circuit failure.

Low voltage circuit common faults: battery saving electricity shortage; Line connection bad or disorder; Bad battery by iron; Distributor hall sensor damage; Ignition switch damaged or bad connection; The damaged transistor ignition control or bad connection. Most of the low voltage circuit fault diagnosis method using ammeter or a voltmeter line by line to detect point of failure.

High voltage circuit common fault: the high tension line loss or leakage; Distributor cap burst breakdown; The distributor rotor ablation burst breakdown; The spark plug electrode gap is too big or too small; The spark plug carbon deposit too much; The spark plug insulator damage; Ignition coil damage or connection loss.

High voltage circuit common fault: the high tension line loss or leakage; Distributor cap burst breakdown; The distributor rotor ablation burst breakdown; The spark plug electrode gap is too big or too small; The spark plug carbon deposit too much; The spark plug insulator damage; Ignition coil damage or connection loss.

2, ignition system does not work:

Switch on the ignition, start the engine, but the engine has no response;

Use high voltage test fire, but high tension line has no spark.

3, early ignition:

Fault phenomenon: idle running is not smooth, easy to remove from heat; Sound speed, the engine has serious denigration

Failure analysis: the failure is mainly ignition timing adjustment assembly misalignment caused by misalignment or ignition Angle.

Method: choose good ignition tester, adjust ignition in advance to the specified value.

4, late ignition:

Fault phenomenon: heavy muffler noise, urgent to accelerate the carburetor tempering, higher engine coolant temperature

Fault analysis and diagnosis: ignition Angle is not correct.

Method: adjust ignition Angle to the specified value.